Proposal to Introduce Automation and Enhanced Digital Traceability into the Red Meat Sector

Thank you for allowing us to outline our technology and how we believe the Livestock Transport Recording System (LTRS) in conjunction with Aglive’s ISC-licensed eNVD traceability platform , offers a comprehensive solution for tracking sheep, cattle, and goats throughout Australia.

It is obviously a priority of Australian Commonwealth, State, and Territory Agricultural Ministers to work collaboratively with industry to advance Australia’s livestock traceability systems. This is crucial for Biosecurity and SafeMeat export programs and is the main reason why all sheep and goats will be individually tagged with eID’s from January 2025.

This is an enormous investment for Government and Industry, and the stakes are very high, it is imperative we give ourselves the best chance of success.

Fitting animals with low frequency RFID ear tags that can be scanned on arrival at a saleyard, feedlot, or abattoir is a great step forward but is only part of the solution, as all this data still has to be manually inputted to third party systems or direct to the NLIS, and what happens about missing tags, and tags not working? A problem that will only be exemplified when all individual sheep and goats need to be recorded after January 2025.

The problem with red-meat consignments is that currently, 70% of vendors still handwrite a paper NVD, and of the 30% using eNVD’s most of those are printed and still go with the livestock carrier as a paper NVD. Paper NVD’s can be lost, damaged or simply unreadable, plus an enormous amount of time is spent uploading data to the NLIS and chasing unverifiable consignments.

The ’Damocles Sword’ of paper NVDs is Biosecurity. It has been proved beyond doubt that paper records are hopelessly inadequate for tracking fast-moving viral disease like FMD if we ever had an outbreak in Australia. Data on animal whereabouts from paper or data-siloed system, cannot be accessed quickly, which is absolutely crucial when it comes to a Biosecurity risk.

The system we have created over 5 years, with the support of MLA and our amazing technology partners, when combined with an eNVD, closes all the loopholes. We have developed a system that is completely passive and autonomous. It will track livestock from PIC to destination, then the LTRS will validate the eNVD on arrival.

Livestock Track Pty Ltd has been working closely with Aglive for well over a year now. It was an obvious collaboration for livestock tracking, as Aglive offers a free, MLA registered eNVD that is logical and much easier to use than paper NVDs.

The vendor simply downloads the app or populates it online, the livestock carrier also has a copy of the eNVD on his device, if there is no service at the PIC as soon as the carrier gets into network service the eNVD uploads and on arrival the consignment is cross validated by the LTRS.

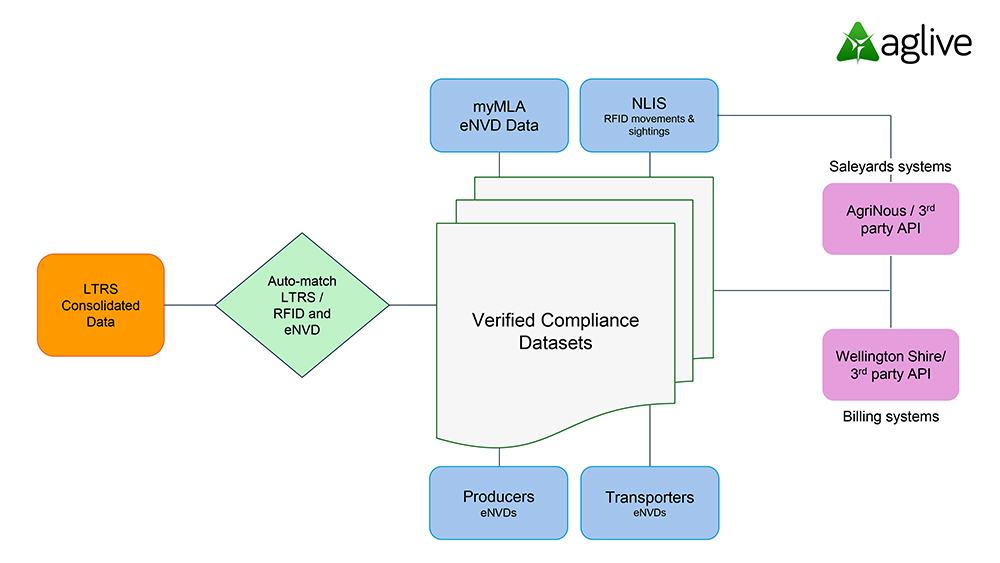

Aglive can also receive eNVDs created directly on the myMLA portal or from third-party systems, making it the ideal integration partner for the LTRS.

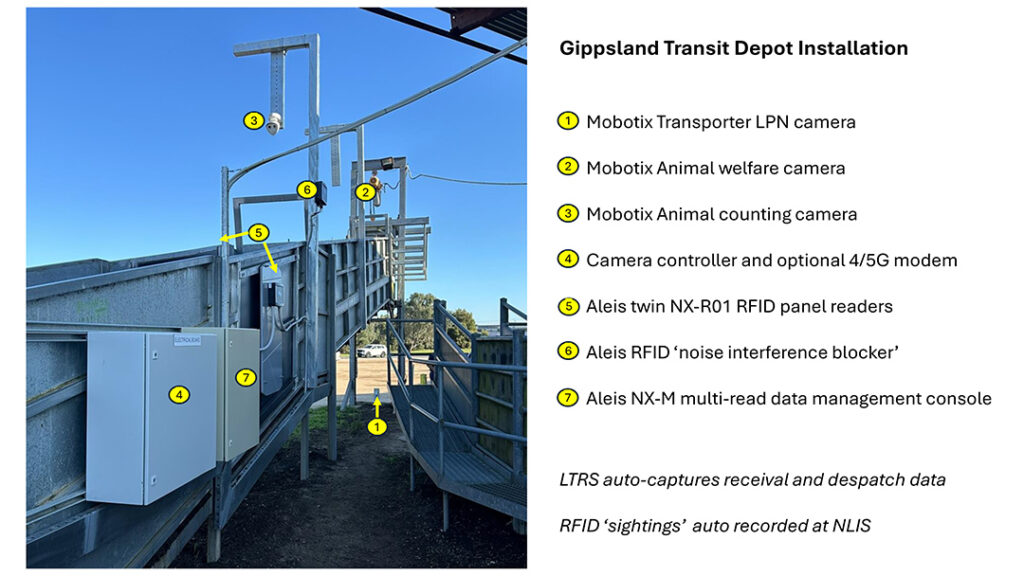

LTRS IN DETAIL

The Livestock Transport Recording System (LTRS) is the perfect tool for cross validating an eNVD. It will work with any eNVD, and its most important function is to ensure that any consignment of sheep, cattle, or goats delivered to the ramp matches the digital eNVD. Here’s how it works:

1. The License Plate of the consignment delivery vehicle is an essential reference, recorded on the eNVD. The first LTRS camera, sitting under the ramp, uses proven Number Plate Recognition software capable of deciphering even the dirtiest of Licence Plates. Every plate is time-stamped and matched with the eNVD.

2. Animal Welfare and WH&S camera will capture all the animals coming off the truck to ensure they are fit and healthy, as well as personnel unloading the vehicle. Both these issues are high priority in commercial livestock facilities. This footage is available for review if there is a problem.

3. A Mobotix MX-1 Camera is used for livestock counting. The counting algorithm is a cloud-based AI program that counts sheep cattle and goats with 100% accuracy. The livestock count, like the truck license plate, is recorded on the eNVD, and in many cases, this number is incorrect. The LTRS counting algorithm ensures the eNVD count is accurate and matches the animal ear-tag data.

4. Every animal delivered to Saleyards, Feedlots or Meat processors must have an MLA-registered eID ear-tag. These devices need to be scanned on arrival, which is currently the only digital reference point. Missing and unreadable tags are common, and animals must be identified, and tags replaced immediately. The LTRS can also extract the eID data from the scanner via an API and cross-references ear-tag count with physical count. If there is a mismatch, animals are identified immediately, saving countless hours of labour and paperwork.

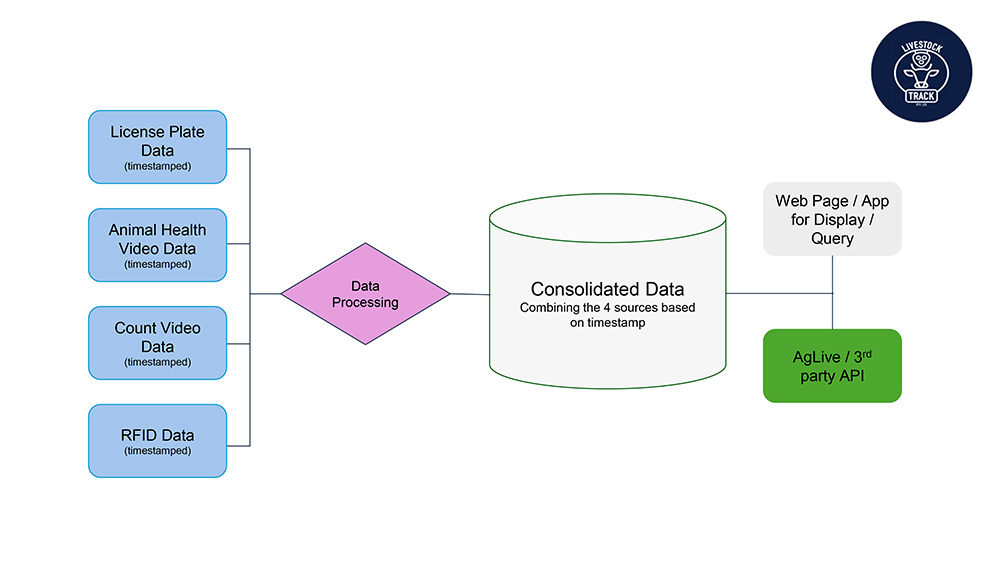

The combination of these four technologies makes up the Livestock Transport Recording System or LTRS.

The LTRS can easily be retrofitted to any livestock unloading or loading ramp. At the same time as the livestock are unloaded from the livestock transporter all the data listed in 1 to 4 above is consolidated on one platform ready for instant download, integration with third party systems or filed.

AGLIVE ENVD

Meat & Livestock Australia (MLA) and their subsidiary Integrity Systems Company (ISC) have been pushing to transition from paper NVD’s to digital eNVD’s for nearly a decade now.

In todays connected world a fully digital platform that records data from paddock or PIC completely through the value chain (ultimately to export plate) is not only logical but essential for knowing where any consignment is at any time, that the consignment is correct at every step and if there is a mistake it is identified and rectified immediately. This can only be achieved on a digital platform which leverages automation of data capture.

The Aglive eNVD like a paper NVD is a record of each consignment, when a delivery of livestock is unloaded at any facility fitted with an LTRS the Aglive eNVD will access the LTRS consolidated platform and compare and validate the delivery data with the eNVD. Mismatches are identified instantly and rectified however if all the data aligns, records can be uploaded to the NLIS, saving countless hours of manual inputting of data from paper. A key Aglive advantage is the ability to integrate farm and supply chain commercial systems providing the capability to verify ‘animal raising claims’ which are vital for premium export markets now seeking GPS logs of origin.

GOING FORWARD

We believe that the Aglive eNVD, in conjunction with Livestock Track’s LTRS, provides a complete answer to tracking and tracing red-meat throughout Australia. The technology can be easily integrated into existing infrastructure and compliments the RFID scanning equipment already installed to read eIDs, which will be mandated for all livestock in the NLIS from January 25.

Victorian Agriculture funded a fully working prototype of the LTRS at Gippsland RLX, near Sale in Victoria, for transit stock. The company was also awarded the National Livestock Traceability Grant through Queensland DPI to instal an LTRS at Roma Saleyards in Central Queensland. Aglive and Livestock Track are planning a national launch of both their technologies in July 2025 at Wagga. With the national mandating of EIDs or NLIS Tags in Sheep and Cattle the LTRS will be an essential tool in the tracking and tracing of livestock through out Australia.

OTHER ADVANTAGES

Thank you again for reviewing our combined technologies for improving tracking and tracing of red-meat in Australia. There are other key advantages of moving to a completely digital platform, which may not be immediately apparent but can be introduced once the infrastructure is in place.

These include:

• Ability to integrate other software programs via APIs such as animal production data, compliance data and selling records all on one platform accessible by registered users.

• Everyone involved in the value chain knowing in real-time exactly where any consignment is at any time.

• Ability to end stock theft by matching ‘muzzle print’ with NLIS eID. If there is a mismatch, it indicates that the NLIS tag must have been changed.

• Biosecurity threats identified and tracked quickly. Additional data helps in decision making at crucial times.

• Breed identification and weight estimate software powered by AI can be included.

• Animal disease identification using thermal imaging and advanced software algorithms.

Importantly, this is not a single provider solution. We are pioneering an industry wide collaborative ecosystem aligned to national and global data standards where other solution providers can participate and help move industry into the digital age.

If you are agreeable, we would like to discuss our proposal in more detail, either through a face-to face or an online meeting. If you have any questions, please revert to either Paul Ryan from Aglive on 0433 128244 or Tye Atkinson from Livestock Track on 0455 927360.

ADOPTION & FUNDING

Similar to the rollout of RFID scanning antennas in commercial facilities to read NLIS tags on sheep, cattle, and goats, the LTRS is simply a more advanced and comprehensive technology for improving the red-meat industry’s ability to track and trace livestock.

The role of Aglive and Livestock Track is to prove beyond doubt to the red-meat industry, including Government Ministers, Federal and State Agricultural Departments, and their extension services, that the combination of these technologies not only enhances existing systems but is also is much easier to use, with retrieval of data been instantaneous and seamless.

If this becomes an undeniable and proven business case in tracking and tracing livestock, the roll-out of the technology should be a given. However, even if industry along with commercial facilities like saleyards, feedlots, and meat processors are convinced, one hurdle will always remain: cost!!.

When presenting this solution, it is critical that a good funding strategy is in place. Many states introduced a rebate system for RFID scanning equipment. The commercial facility spent the money, and the state government would rebate the cost of installation and commissioning. This scheme worked haphazardly, as rebates were only available for certain periods of time, making it difficult for all receival yards to access the funding.

No entity working on a budget, no matter how urgent or important a purchase may be, can cover large capital expense in a short period of time. This may have been an issue with the rebate system!! If we are serious about introducing the best technologies available for tracking livestock, we must also be prepared to fund the solution. Long-term infrastructure loans with low-interest rates, either with government contribution or government backing, are one way for commercial facilities to adopt the technology. There are, of course, other funding models, and Aglive and Livestock Track will explore these avenues.